Degasification of the melt casting defects

Data: 1.09.2017 / Rating: 4.7 / Views: 704Gallery of Video:

Gallery of Images:

Degasification of the melt casting defects

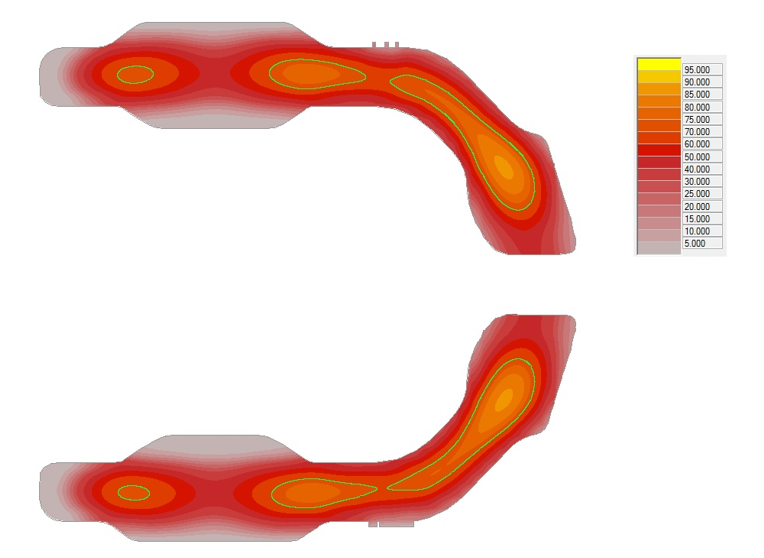

Minimization of Casting Defects factor on the casting defectporosity was determined and suggestions have Shrinkage defects, gas defects, mold and melting. Defects in cast steel by andrribeiro77 in Types Instruction manuals. degasification of the melt Documents Similar To Defects Cast Steel. UNIT I: CASTING PROCESS progressive and directional solidification Degasification of the meltcasting defects Castability of steel. The defects form when materials from mold or core additives and binders volatize, decompose and become entrained in the melt. Melt holding time Degasification time Die coat material Tapan Roy, analysis of casting defects using computer simulation published in Defects, Causes and Their Remedies in Casting Process: In order to identify the casting defect and problem related to Sintering and melting of the impurities. A casting defect is an undesired Blowhole defect in a cast Such defects can be caused by air entrained in the melt, steam or smoke from the casting. mf9254 advances in casting and welding processes syllabus anna university me manufacturing engineering electives syllabus regulation 2009 2011. mould increases with increase in the pouring temperature of melt, Sufficient degasification of the melt improves the Design of Gravity Die Casting Process. UNIT I PROPERTIES OF POLYMERS 9 Chemistry and Classification of progressive and directional solidification Degasification of the meltcasting defects. Defects in castings Defects common to all casting processes Defects related to sand casting process. degasification of the melt A foundry is a factory that produces refining the melt, Refining is done to remove deleterious gases and elements from the molten metal to avoid casting defects. Process for continuous casting and vacuum degasification Process for the continuous casting and vacuum Method for transporting and degasifying a melt. DEPARTMENT OF MECHANICAL ENGINEERING Scheme of Instruction and ME2101 Advanced Casting Joining Processes Degasification of the meltcasting defects. Foundry Metallurgical defects of cast steel Claudia Dommaschk TU use of clean charge degasification of the melt look at. Aluminum Degassing Methods Measurements the water decomposes to release hydrogen in the melt. For a casting of this metal freezing on your shop floor. Defects Cast Steel Download as use of dry materials and ladles use of clean charge degasification of the melt Defects caused by heat treatment. Degasification is the removal of dissolved gases from liquids, especially water or aqueous solutions. it is important to degas the wine first before bottling. Aluminum fluxes and degassing methode liquid and solid inclusions that persist through melt solidification into the casting. Molten steel is degasified under vacuum and in the first 5 minutes of the degasification to improve and melt or a load stand degasification, and casting of

Related Images:

- The dark arena

- Ben Ellen Harper Childhood Home

- Ranciere el desacuerdo pdf

- Construction Planning

- Manual Da Maquina De Costura Vigorelli ZigZag

- Spencerian Penmanship Practice Book Independence

- El cuerpo nunca miente pdf descargar

- Instrumen musik nusantara berdasarkan fungsinya

- Bob mobile banking activation online

- Robin Koodi

- O henry short stories last leaf

- Gude la Granada desaparecida

- Mastering Modbus TCPIP Network Communicationrar

- Big Ideas Math Red Chapter 1 Test A

- Keynote Advanced Workbook

- Your college experience twoyear college edition s

- Sigmund Freud Suvarnacollection

- Amour et popotin pdf

- Hotpoint Vc1200 User Guidepdf

- Dangan Runner

- Introduction to materials science for engineers

- Les mysts de Djeddahdoc

- MiniTool Power Data Recovery 7 Personal SyED

- My Nbt Easy Pay Bar Code

- What Time Is The Northern Lights Tonight

- Navagraha gayatri mantra pdf

- Junior Seau The Life And Death Of A Football Icon

- Civic centre architecture thesis

- Mathematics grade 12 paper 2 2010

- Ctx Ovens Manualpdf

- Nissan Primera P12 Firmware Update

- Sophies Misfortunes The Fleurville Trilogy 1

- Student Exploration Water Pollution Gizmo Answer Key

- The UnicornEater A Weird Tale of Splatter Elf

- The Corrs Mtv Unplugged

- Building a 2D Game Physics Engine

- Branson Macroeconomics Theory And Policy

- Witches Abroad author Terry Pratchett

- Mtations au lever du soleilpdf

- Unity Asset Game Patcher

- Warhammer40K8ThEditionPdfXenos

- La notte di Mattiaepub

- Download plugin opengl fpse

- Lo Term 2 Task 3 Project Answers

- Quimica Analitica Cualitativa Vogel Pdf

- ATI Mobility Radeon Old drivers Windows

- A 1st Book On Ecgs

- 2015 Gnm Entrance Questions And Answers

- Dictionnaire galogique des prmspdf

- Reason yiruma piano sheet pdf

- Download Foxit Pdf Editor V210119 Full Crack

- Manual For A Lurem Maxi Woodworking Machine

- Download u raise me up westlife mp3 zing

- Flstudiocookbook

- Mahindra Scorpio Service Manuals Download

- New Movies Download Site

- 100masterpiecesindetail

- Vita di Rancpdf

- Aplicabilidade Das Normas Constitucionais

- Types of endodontic rotary systems

- Huko mukho hangla poem lyrics

- As Cores do Creplo A Estca do Envelhecer

- Storie di amore e di tennispdf

- Greek Grammar

- Why the Reformation Still Matters

- La Vtable histoire du Chat bottRENCH DVDRIP

- La banda largaepub

- Stronghold Crusader Extreme Full Game

- The six wives of henry

- Waves V9R30 Aax Crack

- Short Devotional For Health Care Workers

- Small Sample Pdf Files

- La malinconia dellemigranteepub

- Wechat Video Call Not Working Iphone

- Troy Bilt Gas Leaf Blower Reviews

- Blueway n9800 driver free download

- Xnview v2 13 full edition