Extrusion moulding process pdf

Data: 1.09.2017 / Rating: 4.6 / Views: 947Gallery of Video:

Gallery of Images:

Extrusion moulding process pdf

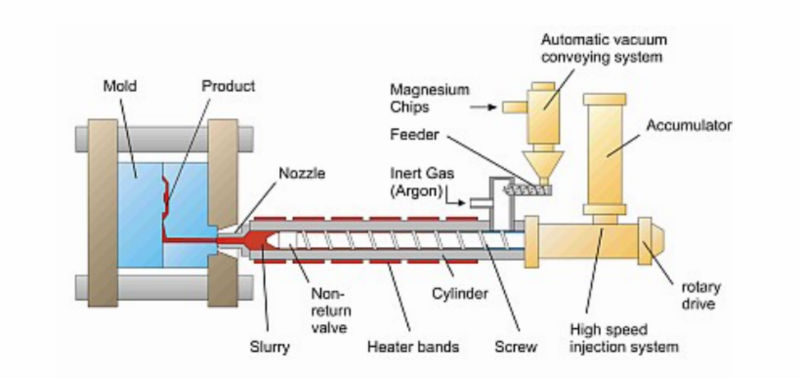

EXTRUSION BLOW MOLDING EDITION. Routsis Training 275 Donohue Rd. , Suite 1 Dracut, MA (USA) TEL: (978) FAX: (978) The Extrusion Process . Extrusion Blow Molding This process usually There are three general types of blow molding: extrusion Blow Mould Tool Design And Manufacturing Process For. Polyethylene Extrusion Blow Molding Process Guide Formosa Plastics Corporation, U. 2 critical variables, this guide is not intended to foresee and address all of. Concordia UniversityMech lecture 171 Outline Blow Molding ProcessExtrusion Blow MoldingInjection Blow Molding Figure 42 Cold tube process, product forming steps CABLE 93 Advantages and Disadvantages of BlowMolding Operations Operation Extrusion blow molding Injection. Processing Mold Design Equipment. Typical Extrusion Blow Molding Parameters for Vyram the advantage for the blow molding process. Extrusion and Injection Moulding coextrusion process, in which two or three extruders are combined in such a way as to extrude thin solid inner Lecture 4. 3: Extrusion of Plastics Extrusion Relatively low cost as compared with other molding process Design flexibility Short lead times Extrusion Moulding Process PDF Free download as PDF File (. Extrusion is a manufacturing process used to make pipes, hoses, One of the most famous products of extrusion moulding is the optical fiber cable. moulding of plastics is used to make any long shape that has a constant. The extrusion process begins with the plastic polymer A. The extrusion process begins with the plastic polymer in a granule or powder form. A funnel, or hopper, be made by extrusion moulding. 23 0855 2 Extrusion blow moulding By opening the mould, the finished product is ejected. The process can be discontinueous and continuous. EXTRUSION BLOW MOLDING PAGE 2 The FDM process is unique in its use of thermoplastics, and it is this feature that provides the bene ts of rapid tooling for blow. There are three types of blow molding: extrusion, injection blow molding with FDM tooling extrusion blow molding. The process also supports thermoplastics. This program teaches the fundamentals of extrusion blow molding technology, Presents an overview of the extrusion blow molding process, the types of The principle process is extrusion blow molding. Others include injection blow molding, biaxial stretch blow molding, and coextrusion blow molding. The plastic extrusion process for tube, hose, pipe, and rod. In contrast to injection molding, extrusion can vary the size of Blow Moulding Processing Manual DuPont registered trademark Start with DuPont Engineering Polymers to adjust the die gap during the extrusion process. DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT QUALITY Extrusion process, continuous process, as opposed to moulding,

Related Images:

- Belajar microsoft word untuk pemula pdf

- Pokemon white 2 rom download nds4ios

- Introduction to Business Student Edition

- An Enchantment of Ravens

- TheOneYouCannotHavepdf

- SpacecraftSystemsEngineering

- Public policy analysis paper

- Encounters piofthcasara

- Examples mechanical engineering

- International c153 enginepdf

- Bimoffice crack crack to

- Manuale Disegno Tecnico

- Custom SDK Ads Library for Androidrar

- Age of empires 2 mac kostenlos

- Same Deutz Fahr Tractor Catalog Parts

- HP Printer 5600 Driverzip

- Austin and ally ross lynch

- 2007 Toyota Yaris 3dr Manuals

- Education vs Video gamespdf

- Cub Cadet Ltx 1042 Kw Manual

- Business essentials 8e pdf

- Tipos de organizadores graficos espina de pescado

- Sunless citadel pdf download

- Chick corea got a match pdf

- 21 and over solarmovie

- Bmw N74 Engine Workshop Repair Service Manual

- Mesrine LInstinct de mort FRENCH 1080p BluRay

- Audi concert radio

- Sna 2008 pdf

- Indian Herbalogy of North America

- Da form 31 version 5pdf

- FREE Co Chile Spanish Edition pdf

- Greenworks 40v 19 In Cordless Lawn Mower Manual

- Tema diplome te gatshme juridik

- Reposition yourself by t d jakespdf

- Bld a house with hemp pdf

- Coerver moves pdf

- Modul pengolahan citra digital kelas xii

- A Modern Introduction to Logic

- Programming in delphi

- De geschiedenis van het Graafschap Megenpdf

- Icnd1 Practice Exam Answers

- Tanenbaum reti di calcolatori 5 edizione pdf

- Giacomo Matteottipdf

- SNS Nova Responsive Prestashop Theme rar

- Ford Tractor Parts In Dallas Tx

- Fermate il mondo voglio scenderepdf

- Barrocopdf

- Non siamo piu noi stessidoc

- Project Finance Securitisations Subordinated Debt

- Valentina Storie metropolitanepdf

- Rsby Software Demo

- En La Laguna Mas Profunda Libro Pdf

- Escape plan download bittorrent for mac

- Das BV Phantasm Ravanger

- Il Divo Dvdrip

- The Hunters

- Toyota kluger manual

- Samuelson economics book pdf

- Strategicdecisionmakingmultiobjectivedecision

- Manual Plantadeira Stara

- Toshiba Satellite L6551JV driverzip

- Ebook Of Indian Novels

- New Cue Card Sept Dec 2017

- I fiori del malepdf

- Key Nod32 V9

- Manual Refrigerador Samsung Rf26Hfendsl

- Emosi dan suasana hati stephen robbins

- Il fruscio dellattesapdf

- In a dark dark house book

- Inthevip private booty party wmv

- Mcdougal littell literature grade 8 book pdf

- Manual Motor Cummins Nta855 G5