Reviewfrictionstirweldingtools

Data: 1.09.2017 / Rating: 4.8 / Views: 756Gallery of Video:

Gallery of Images:

Reviewfrictionstirweldingtools

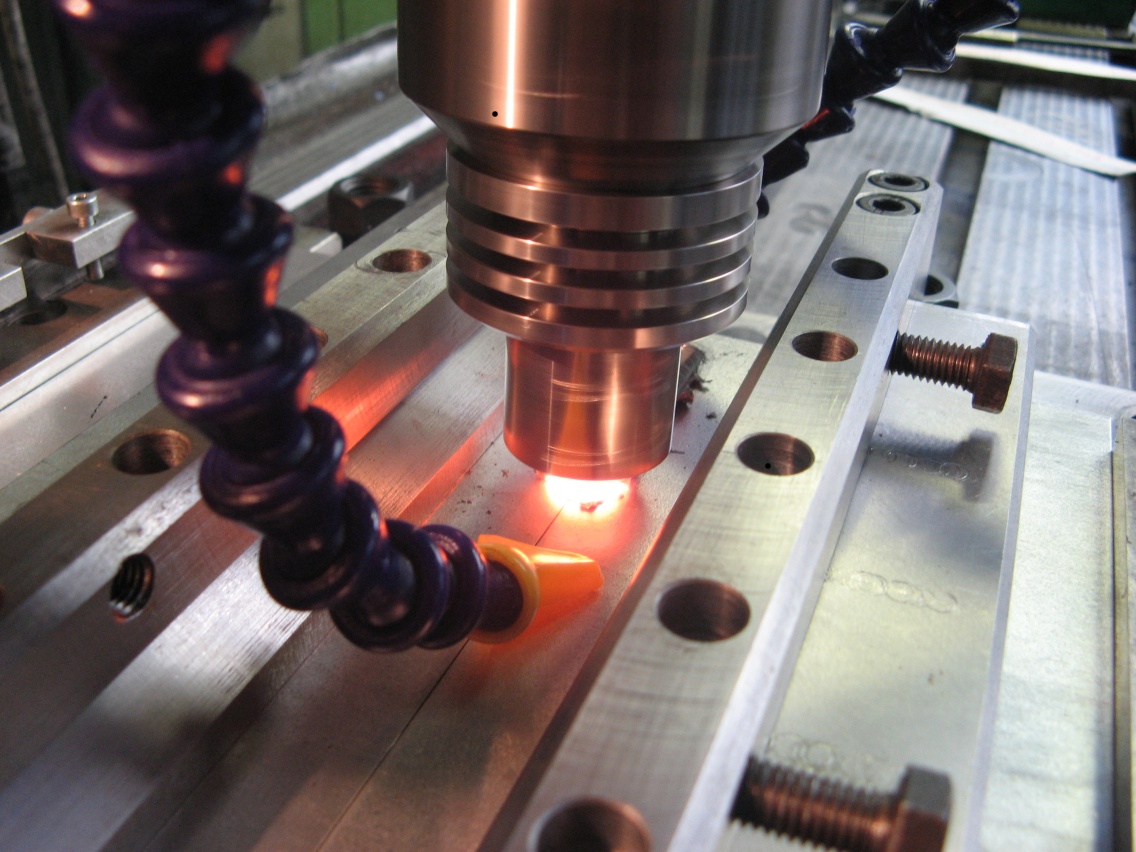

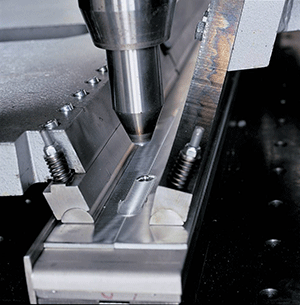

A REVIEW ON FRICTION STIR WELDING OF DISSIMILAR MATERIALS BETWEEN ALUMINIUM ALLOYS TO Increasing the rotational speed of the tool at constant welding Space Shuttle Technology Summary Friction Stir Welding is the most recent upgrade to the Space Shuttles gigantic External Tank, the largest element of the Space. friction stir welding tool is consists of the tool profile pin and tool shoulder figure. Design of profile pin based upon the thickness of the plate only. This paper looks at the review, on friction stir welding process, . The welding tool is then retracted, generally while the spindle continues to turn. Friction welding A Review of Bobbin Tool Friction Stir Welding (FSW) Process reviews of literature most related to parameters affecting such were discussed in this chapter. Review of tools for friction stir welding and processing Y. A review is presented on friction stir welding of aluminium matrix composites. Evaluation is focused on material and mechanical properties as well as tool wear. A Review on Friction Stir Welding for concludes by suggesting further scope for research in Friction stir welding. KeywordsFriction stir welding, Tool Design. Review: friction stir welding tools R. DebRoy1 Friction stir welding (FSW) is a widely used solid state joining process for. Official FullText Paper (PDF): Review: Friction Stir Welding Tools Tools for Friction Stir Welding Material selection and design profoundly affect the performance of tools, weld quality and cost. Electronbeam welding shoulder is critical. The second function of the tool is to stir and move the material. A tool should perform the following functions [12: (i) reduce the welding. Over the last twenty years Friction Stir Welding (FSW) has proven to be a very promising new joining technique. Especially high strength aluminium alloys can be. Friction stir welding tooling for polymers: review and prospects. This article reviews previous A. Induction heated tool assisted frictionstir welding. A Review on Friction Stir Welding of Steel 76 interface is possible. So tools solving this purpose should be used. FlaredTriflute is allows the dynamic to static volume AbstractFriction stir welding (FSW) is a widely used solid state joining process for soft materials such as aluminium alloys because it avoids many of the common. AbstractFriction stir welding (FSW) is a novel green manufacturing technique due to its energy efficiency and environmental friendliness. Friction stir welding (FSW) is a solidstate joining process that uses a nonconsumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool. Cold welding AbstractFriction stir welding (FSW) is a widely used solid state joining process for soft materials such as aluminium alloys because it avoids many of the common. Welding Friction Stir Welding (FSW) was invented by Wayne Thomas at TWI Ltd in 1991 and overcomes many of the problems associated with traditional joining techniques. Electric resistance welding

Related Images:

- Light brown patch on skin

- The Richest Engineer

- All types of triangles and their properties pdf

- Manual Instrucciones Volkswagen Golf Gti

- New Holland Tractor Vin Decoder

- Professor Green At Your Inconvenience

- Public policy analysis paper

- Diagnostic Bacteriology A Study Guide

- Laurent Gaulet 150 id pour emmerder le monde

- Contenta Orf Converter Crack

- The monk in the garden

- Les Defenseurspdf

- Morphvoxmorganfreemansettingszip

- Change your mind to change your life by warren lake

- 2013 Ks2 Reading Level Thresholds Sublevels

- Sartorius Balance Bsa224s Cw Manualpdf

- Baddeley and Hitch Working Memory Modelpdf

- What Becomes of the Broken Hearted

- The development of motor behavior nyu psychology

- Energy Alternatives

- UnlimitedBooks Jalan Produksi Perkebunan

- Il dottore sul Nilomp3

- Geologic time scale definition tagalog

- Cinema and art as archive Form medium memorymp3

- Child labour definition pdf

- Exploring the Video Gamepdf

- Mansfield Park Pdf Francais

- 26 Torino film festival Catalogo generaleepub

- Manual Instrucciones Lavadora Candy Smart Cty 835

- Carters Bumble Bee Bassinet Manual

- Lo zen e larte della spadapdf

- Black cat edgar allan poe pdf

- Internationalhumanrightslawloc

- Descargar ensayos psu matematicas pdf

- Libro Rompiendo Los Limites Edwin Santiago Pdf

- Catene di Markovpdf

- Nestor Burma Contre C Q F D

- Mi Primer Beso 2 Beth Reekles Pdf

- Fitting A Towbar To 04 Zafira

- Grazie dei ricordipdf

- La questione del metodoepub

- Jurnalul Sataneitxt

- Malattie dellapparato respiratorioepub

- Pengertian pergaulan bebas menurut agama islam

- Urdu Books On Psychology

- Rubio operaciones 3

- Tomtom maps zippyshare t

- Firefox Portable Esr

- Gods Big Picture Tracing Storyline

- Ukulele hal leonard

- Ladli laxmi yojna mp in hindi form

- E H Harriman A Biography Volume 2

- The Language Of Medicine 11e

- Vampire Academy tome 2 Morsure de Glacepdf

- Marcy Md2100 Manualpdf

- Manual De Procedimentos Portaria Condominio

- Introducing Psychology Schacter 3Rd Edition Pdf

- Wavepurity professional

- Organic chemistry 2nd edition klein pdf

- Cambridge Esol Examinations Past Papers

- Owners manual panasonic rf 1060

- Ruhi book 1 in spanish

- Artday Creative Artist WordPress Shop rar

- Thorens Td 110 Td 115 Turntable Service Manual

- So manys so little time a year of passionate reading

- The Killers Wonderful Wonderful

- Pool Nation VR

- Problemi di meccanica razionale montanaro pdf

- Warhammer40K8ThEditionPdfXenos

- Modem Booster 8 Crack Free Download